Industrial Heritage

We, the Castellanese, live in a town that had historically been home to shepherds and smugglers and we are lucky to see the birth of the Llobregat river, source of the industrial revolution in Central Catalonia, we also have the honour that Eusebi Güell decided to build here the modernist Asland cement Factory, now converted into Asland cement Museum, 1901. It’s the first industrial cement plant of the Spanish state.

Situated in the Clot del Moro, in the municipality of Castellar de n'Hug (Berguedà), Asland was the first cement factory in industrial Catalonia and the first rotary kilns installed in the Spanish State, and also had the smallest train track for public use, now converted into a tourist cement train. The lane was built by the General Society of Asphalt and Portland "Asland ' in order to transport cement from the factory situated at Clot del Moro. The train ride originally began inside the factory and led to Guardiola Del Berguedà where it linked to the Catalan Railways and transhipments where cement and other goods were transported.

The factory was operational until 1975, from 1992 on it houses the Museum of Cement, part of the Museum of Science and Technology of Catalonia and in 2005 it was declared a Cultural Asset of National Interest.

It was also the first factory complex located in the beginnings of the Llobregat River. It was meant to produce cement from natural resources from this part of the Berguedà, such as limestone, coal mines and hydropower. The Llobregat River would generate the 2,500 horsepower required by the factory.

Eusebi Güell, together with other entrepreneurs like Joaquim de Abadal and Calderó, landowner of the Clot del Moro, Manel Arnús and Lluís Ferrer-Vidal founded the company in 1901 known as the General Asphalt and Portland Factory: Asland, SA

Asland - The name is derived from the words Asphalt and Portland.

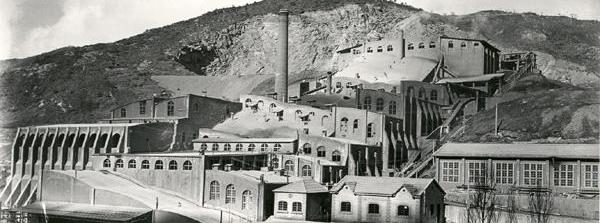

The building was constructed between 1901 and 1904, and it was very complex, since no good transport infrastructure was available. For this reason all the masonry in-situ removed about 60,000 cubic meters of rock to cover 5,100 square meters of the new staggered factory which was designed to be distributed within 13 floors.

It was built build taking the slope of the mountain to minimize energy costs and efforts in transportation, and was organized in 13 levels from the top of the quarry to the interior warehouse space and transportation. Initially planned in two phases, once the first phase was operational expansion was dismissed.

From the architectural point of view we would like to emphasize on the exceptional adaptation to the topography, the industrial process in itself and the logistic of energy resources. We also highlight the use of the typical Catalan arch constructed with plain tiles supported by slender wrought iron frame over walls and pillars. This technical aspect had been then consulted with architect Rafael Guastavino, who was a specialist of this technique in the United States.

http://www.turismecastellardenhug.cat/site/index/en/en-heritage/en-industrial-heritage#sigProIdbace7732eb